Export-Ready.

Guaranteed Safety & Freshness

Global Shipping

Fast export logistics to 30+ destinations.

Modern Processing Plant

EU-grade lines with HACCP & ISO 22000.

Instant Freezing Technology

IQF blast freezing locks in texture & color.

Certified Quality

Batch-tracked, lab-tested, export grade.

About Us

In the Turdisan group, with inspiration from Grimma and Energy Khorshid, there is a mission to generate and display new materials with standard quality and quality. A slogan: “Tardisan; “Pakhti Asan” is the best thing to do, so that my crops are safe, healthy, and good to eat.

I pride myself on the fact that there is a store of produce that we end up in an indoor bazaar, but also in a different market where there is a supplier of receiving the decision of his room and the satisfaction of buyers among the people who want to bring food. Guided by the quality, Bestabandi Bahdashti and the care of the standards of my exports are among the most important principles.

What is the point of achieving realistic success with the satisfaction of buyers? Tim Tardisan carefully and diligently tries to find out the products of his packages, which are diverse and consistent with the needs of the Jahani Bazaar. How to install the type.

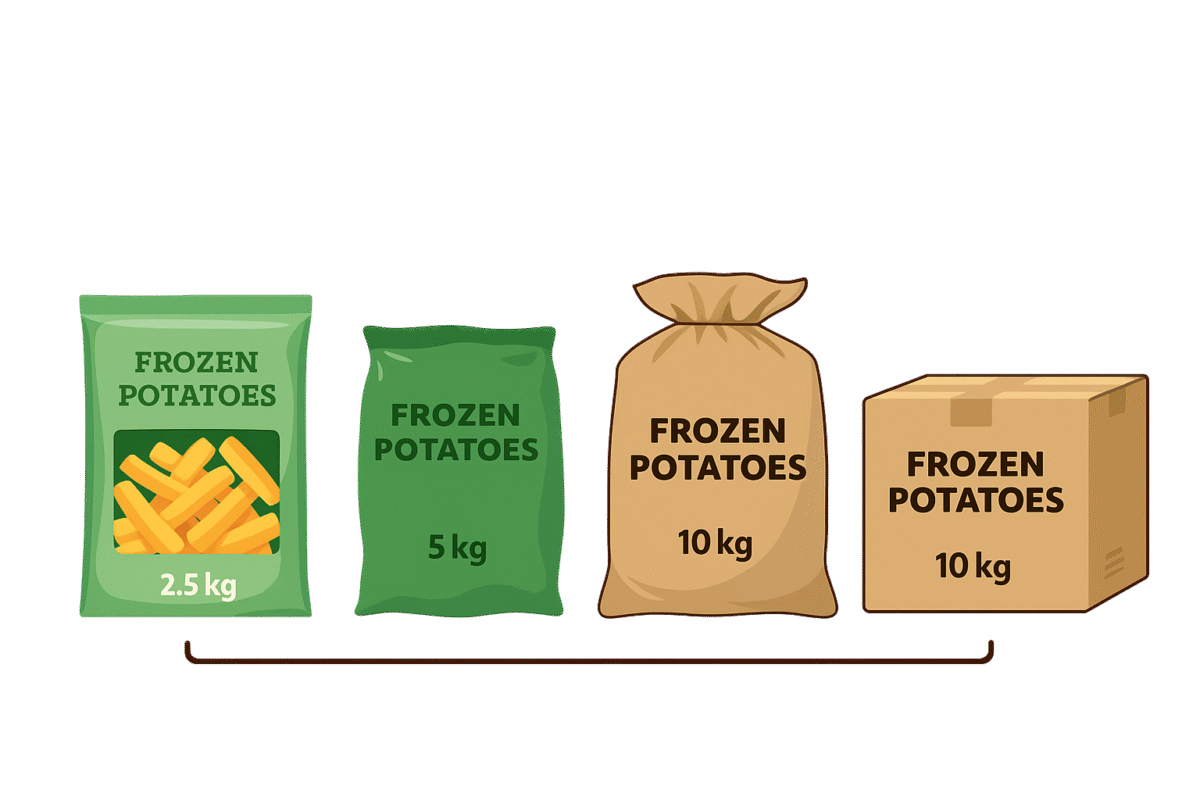

Choose Your Perfect TORDI SUN Package

2.5KG Grade

Perfect choice for home use, cafés, and small distributors. Easy to store and cook.

5KG Grade

10KG Grade

Designed for industrial buyers and exporters. Maximum efficiency and long shelf life.

Our Achievements at a Glance

Tons of Premium Half-Fried Potatoes Exported

Export Destinations Worldwide

Certified Quality Inspections Each Month

Trusted Clients in Food Industry

Certified Quality

You Can Trust

Every potato is selected from premium farms, processed in a hygienic environment, and frozen instantly to preserve its natural texture and taste.

We follow ISO 22000, HACCP, and HALAL standards to ensure top export quality.

From Farm to Freezer – The Perfect Process

Our production chain ensures quality at every step:

Cultivation

Grown in nutrient-rich soil using sustainable farming practices.

Harvesting

Picked at peak maturity to preserve ideal texture and flavor.

Sorting & Washing

Sorted by size and quality, then thoroughly washed.

Peeling & Cutting

Automated peeling and precision cuts: straight, crinkle, or wedges.

Blanching

Brief hot-water blanching stabilizes color and texture.

Pre-Frying

Light pre-fry in high-quality vegetable oil for a golden surface.

Quick Freezing

Flash-frozen at −40°C to lock in freshness and taste.

Packaging

Packed, labeled, and sealed under strict hygiene standards.

Storage & Distribution

Stored in cold warehouses and shipped worldwide via cold chain.

FAQ

7×7 mm, 9×9 mm, 10×10 mm, shoestring, crinkle, and wedges. Custom cuts on request.

2.5 kg, 5 kg, and 10 kg food-service packs in export cartons. Private label and artwork support available.

One 20’ reefer container (≈24–26 MT net, depending on mix and packaging).

Typical production lead time is 12–18 days after artwork/PO approval; dispatch depends on vessel schedules.

18 months at −18 °C or below. Avoid temperature fluctuations during the cold chain.

Fry at 175–180 °C for 2–3 minutes until golden. Do not thaw before frying.